-1.jpg)

TESTING AND CERTIFICATION

Quality is a way of life at C.Lal. We are committed to maintaining a competitive edge within the automotive industry and beyond. We believe that through the use and development of technology, along with the skills of our people, we can process material to satisfy our customer’s quality standards and delivery requirements at a competitive price. Our unique reference number traces each bar through the production process right to the raw material source.

SELF CERTIFICATION

Every heat of steel received is tested for Chemistry, Hardness, and physical properties to gauge the various properties of steel. C. Lal's Quality Assurance Department provides a Certified Test Report (CL/QC/04) to confirm chemical and physical results. This report is combined with our invoice for easier record-keeping for our customers.

EDDY CURRENT METAL SORTER FOR GRADE VERIFICATION

Eddy Current metal sorter checks steel chemically beyond doubt. Non-Destructive spark test is used regularly as a means of product grade verification qualitatively.

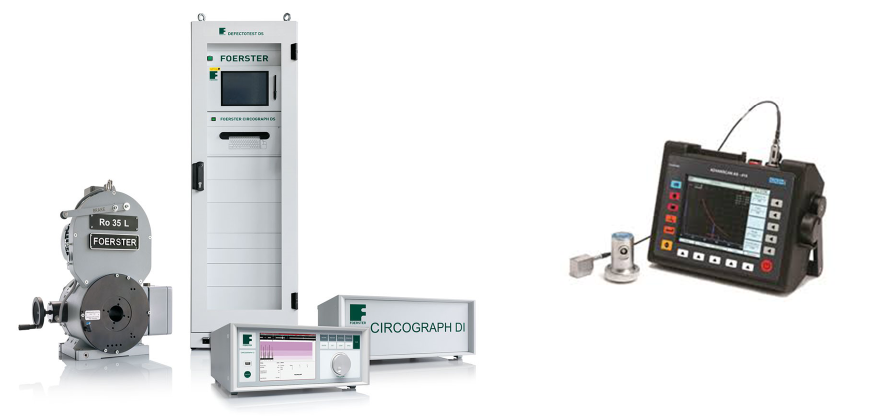

EDDY CURRENT, MAGNAFLUX, AND ULTRASONIC TESTING FOR DEFECTS

Fully automated Dr. FOERSTER eddy current test system with rotating probes guarantees maximum detection sensitivity for exposed longitudinal and transverse surface defects on bright material. Our 3-Meter Magnaflux machine reveals all Surface and next-to-surface defects showing their length, intensity, etc. The fluorescent magnetic powder makes visible even the minor seams, which are otherwise not visible to the human eye. Ultrasonic Test reveals all internal defects of steel which would otherwise pass on and prove hazardous.

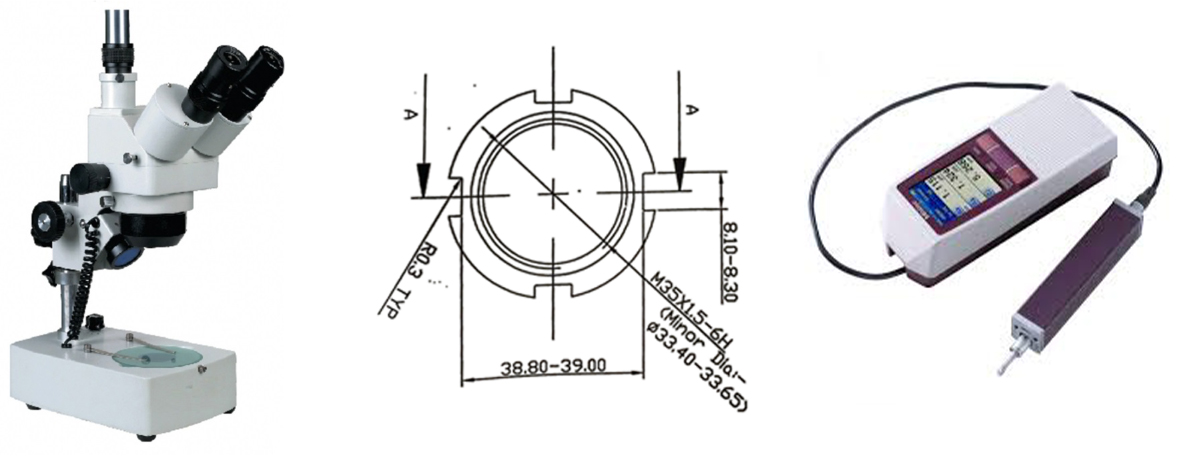

PHYSICAL/MECHANICAL ANALYSIS

For Physical and Metallurgical analysis we are equipped with Brinell cum Rockwell Hardness Tester and Universal Testing Machine. Straightness is also a crucial deciding factor in the quality of the bright bar. Utmost care is taken to check the straightness of each lot statistically. As a standard, any bar not conforming to the standard 0.5 mm per meter has to be re-straightened.

DIMENSIONAL CONTROL AND SURFACE FINISH

A series of 2 point and 3 point Micrometers ensures that diameter and Ovality are measured with great accuracy. Carbide dies are used for 100 % of the production to ensure the drawn steel is not prone to any Ovality or size variation. Extra care is taken to control and check Ovality on peeled and ground bars. Surface Roughness Tester ensures that exact Ra, Ry, Rz values are maintained on ground bars.